category_news

Innovative method offers new possibilities in 3D printing of food

3D printing of food is becoming more and more popular and sophisticated. As part of the Digital Food Processing Initiative, TNO, Wageningen University & Research and Eindhoven University of Technology are working on a new printing method in which two material flows come together smoothly. This method – continuous switchover printing – makes it possible to create interesting designs and functionalities. Kjeld van Bommel, who was closely involved in this innovation, is enthusiastic about the new possibilities.

Can you describe continuous switchover printing?

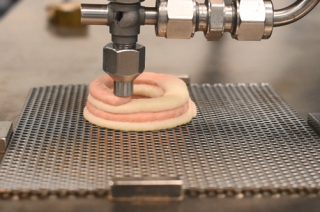

'We have found a way in which we can seamlessly switch between two material flows from a printer. We have developed special print heads for this.

Over the past years we have been working a lot with coaxial extrusion printing, a printing technique in which two materials are combined in a single printing head that extrudes a filament composed of a central core and a surrounding shell material with which a 3D object can be printed. By using this technology we have been able to print, for example, filled pasta composed of walls of pasta dough filled with channels of cream cheese. Analogously we have used the technology to print biscuits made of dough filaments with central air channels that provide specific levels of porosity to the biscuit.

Recently, however, we have also started using these coaxial nozzles for other purposes, specifically continuous switchover printing. Rather than extruding both materials simultaneously and creating a core-shell filament, we extrude the two materials in an alternating version, i.e. switching from material A to material B and back. Dual material printing is not new, but is normally done using two individual printing heads that deposit their materials A and B in an alternating fashion. Hereto nozzle 1 deposits material A, then moves away and nozzle 2 comes in to deposit material B, etc. However, this often results in printed objects with defects, as upon switching of the printing head and moving away of the nozzle the deposited material shows a small blob (similar to when you use a piping bag to deposit whipped cream; at the end you typically see a “pointy bit” sticking upward). When depositing layer upon layer, these defects accumulate and can result in a messy or even failed print.

By using our coaxial nozzle it is possible to print in an alternating way with 2 materials in a continuous manner, allowing for smooth switchovers between the two materials and thus defect free printing. This enables us to print high quality products with complex designs and textures, not feasible with other printing technologies.’

- Unfortunately, your cookie settings do not allow videos to be displayed. - check your settings

What can this method be used for?

‘We can use this to print even more interesting designs, such as pastries where only specific parts contains yeast or another leavening agent, resulting in programmable shape alteration upon baking and related to that, sections with different textures. This development brings us into the domain of 4D printing, 3D printed objects that contain programmed information that is expressed after an external trigger (time, temperature, or other).

Of course it can also be used for “regular 3D food printing”, such as the creation of chocolate or candy objects with sections that switch seamlessly from one color or flavor to another. Or any other application where specific localized contrasts or gradients in texture, flavor, or color are desired.’

What does the future of 3D and 4D printing look like?

‘There is a lot of interest in personalized nutrition. The idea is that more and more food will be printed that is precisely tailored to the nutritional needs of customers. For example, the exact same muesli bar will not be manufactured for everyone, but personalized to your desires and needs. Extra protein for a top athlete, extra iron for someone else, it's all possible. As multiple material need to be deposited, a wide range of textures is desired and printing defects should be avoided, coaxial as well as switchover printing can play a role in this.

Personalization not only is important with food, but also with medication. In another project we are working with Erasmus University and Sophia Children's Hospital. Pills come in a standard size, but in some cases you need a different amount. Then the pharmacists have to cut the pills themselves by hand. With a 3D printer in a hospital pharmacy, the pharmacists can print personalized tablets with a weight that matches exactly what each individual patient needs. I think these are very positive developments.’